In winter, "Six Seasons" helps you keep warm and warm during the breeding period

The temperature drops significantly in winter, making it difficult for the chicken coop to maintain insulation and the water supply system to freeze. This affects the blood circulation and nutritional metabolism of the chicken flock, leading to a decrease in their immune system. This is beneficial for the survival and transmission of pathogenic microorganisms, and increases the risk of respiratory and bacterial diseases.

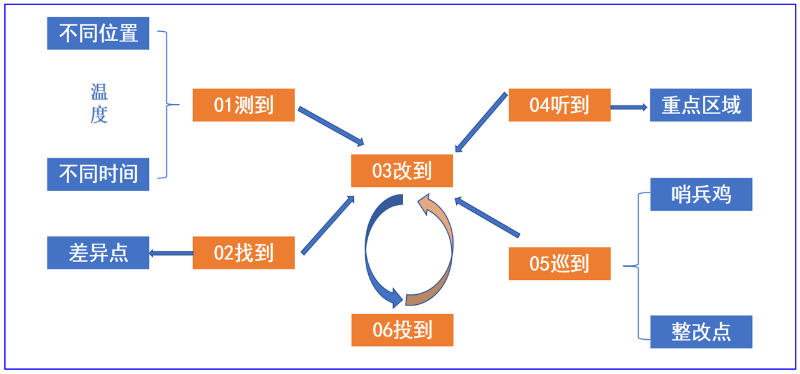

For breeding farms, the key to winter chicken breeding management is to do a good job in cold prevention and insulation. The goal of keeping warm during the breeding period of chickens is to prevent respiratory tract infections and secondary mycoplasma infections. The main measures are to implement no temperature difference changes, no respiratory diseases, and preventive medication in the building, and to achieve "six in one" (detection, finding, improvement, hearing, patrol, and delivery) management and chicken house environmental control management.

1、 Management Measures for 'Six Visits'

By measuring the temperature at different locations and time periods in the chicken coop, identifying the differences and problems, and carrying out rectification; After rectification, the effectiveness of the "improvement" will be tested through auscultation and inspection of the chicken flock. If there are still problems, targeted medication will be administered. Repeat this process until the rectification is completed.

1. Detected

Understand the structure and environment of the chicken coop, measure the size of the structure, water curtain, and small windows of the coop, and monitor the temperature, humidity, static pressure, and wind speed inside the coop for any abnormalities.

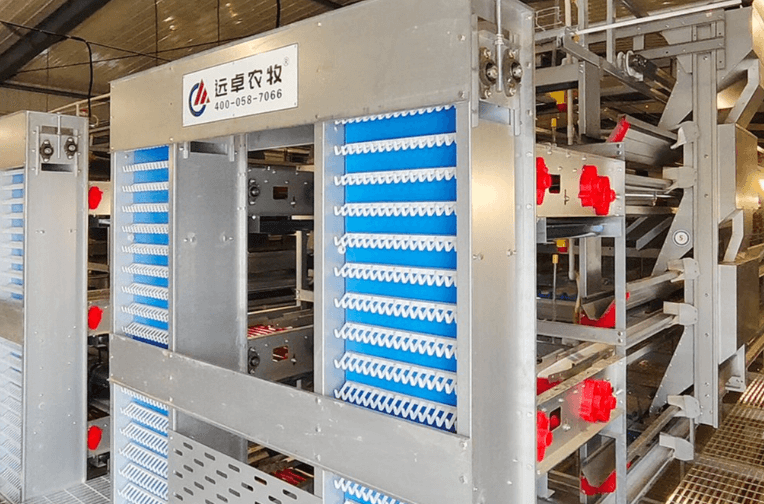

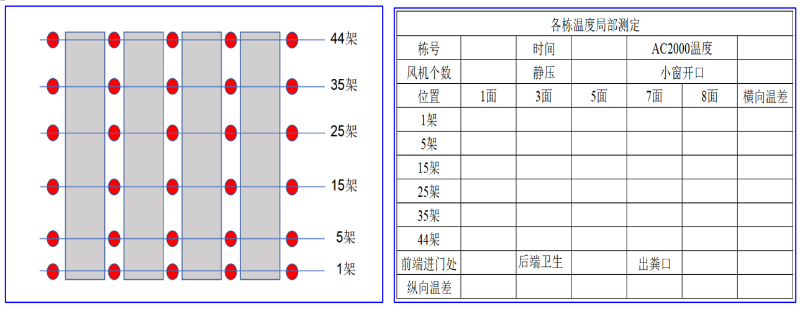

Based on the situation of the chicken coop, temperature and wind speed measurement points are set up according to the time point (external weather changes) and location (uniform distribution). Taking the example of a 3-layer A-type cage with 4 columns, one thermometer is installed on each side at 1, 5, 15, 25, 35, and 44, and a total of 30 thermometers are installed at the same height (upper edge of the middle material trough) for temperature monitoring.

2. Find it

Based on the changes in horizontal and vertical temperature differences within the building, identify the source of the problem, such as the low temperature points in the front and rear of the building, such as front and rear doors, fans, manure ditch openings, insulation boards, etc. Find scattered points, locations where the cause cannot be found, and unresolved temperature differences within the venue, and use leadership resources to help analyze the reasons for the existing problems.

3. Change to

By analyzing the "measured" data, identify the risk points of the building for rectification, such as using door curtains for the front door of the building, blocking the cleaning port, uniformly symmetrical small window openings, sealing water curtain insulation boards, and wrapping unused fans. After rectification, re measure the temperature at each point and verify the effectiveness of the rectification.

4. Heard it

Establish a respiratory auscultation system for on duty personnel, and record the types and proportions of respiratory auscultation. Provide timely feedback in case of special circumstances; Focus on marking and auscultating areas that are prone to problems, determine locations with more respiratory tract infections, administer medication at designated locations, and manage them at designated locations.

5. Patrol to

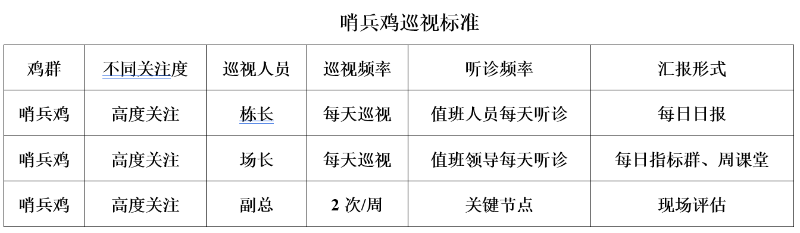

Establish a process and standards for chicken flock inspection, clarify the breeding environment, production indicators, chicken flock status, etc., and keep 24-hour duty records.

Based on factors such as breeding varieties, experience of building managers, and years of work experience, three areas of concern for each building are determined. Sentinel chickens are set up in areas prone to problems, and the proportion of abnormal chickens in the flock is separately counted. Sentinel chickens are auscultated daily, and medication is administered promptly if there are problems.

6. Invest in

Administer medication separately before the critical age and milestones of the chicken flock to prevent respiratory tract infections. Administer medication separately before temperature changes in the highly monitored area, and accurately diagnose the disease based on symptoms in large/small groups, and determine whether to increase the dosage of medication in the highly monitored area.

2、 Chicken coop environmental control management

The main factors affecting the health of winter chicken flocks are air quality, cold stress, and stress accumulation.

1. Air quality

Firstly, choose the appropriate ventilation mode. Adopting the minimum ventilation mode ensures oxygen supply and harmful gas discharge in the chicken coop while minimizing heat loss to the greatest extent possible. The opening of the small window is set to 2.5cm, so that the fresh air entering can be evenly distributed at the top of the chicken coop, fully mixed with the polluted air inside the coop, and then slowly sinking to avoid direct cold air blowing onto the chicken flock.

Secondly, clean the feces once a day, search for water leakage points, and reduce the harmful gas content in the house. Pay attention to watering during ground cleaning to avoid dust rising. Watering can be done at the highest temperature point in the afternoon to achieve humidification and dust reduction effects.

In order to achieve a balance between ventilation and insulation, during the actual adjustment process, some ventilation volume can be sacrificed to achieve a suitable temperature in the chicken coop, ensuring the health of the chicken flock and preventing respiratory tract infections.

2. Cold stress

Pay attention to weather forecasts in advance, grasp the patterns of winter climate changes, and prepare contingency plans. When the temperature drops sharply, the ventilation parameters should be adjusted quickly. By reducing the ventilation volume, the room temperature can be maintained to ensure that the minimum temperature drop in the room is controlled within 0.5 ℃~1 ℃ compared to the previous day.

Take preventive measures against local cold stress. Seal doors and windows properly, install sealing strips or door curtains at the edges of doors and windows. The gaps between the water curtain insulation board are sealed with transparent tape, and unused fans are covered with plastic cloth to prevent cold air from penetrating. Regularly inspect the sealing of doors and windows, promptly replace damaged sealing strips or repair poorly sealed areas to ensure the sealing of the chicken coop.

3. Stress superposition

Under the condition of ensuring that the weight of the chicken flock exceeds the standard by 3% to 5% and the proportion of respiratory tract is below 0.5%, combined with the cooling node, adjust the time of stress occurrence such as material change and group transfer reasonably to avoid the superposition of stress.

The cold and warmth prevention and control work of winter breeding chicken flocks is a systematic and complex project, which requires farms to take comprehensive and effective measures from multiple aspects such as chicken house environment regulation, heating equipment management, ventilation and air quality assurance, and disease prevention and control. Only in this way can we ensure the healthy growth of the chicken flock in the cold winter, smoothly pass the breeding period, lay a solid foundation for subsequent egg production or slaughter, and achieve the economic benefits and sustainable development of the breeding farm.