Chicken Brooding Equipment

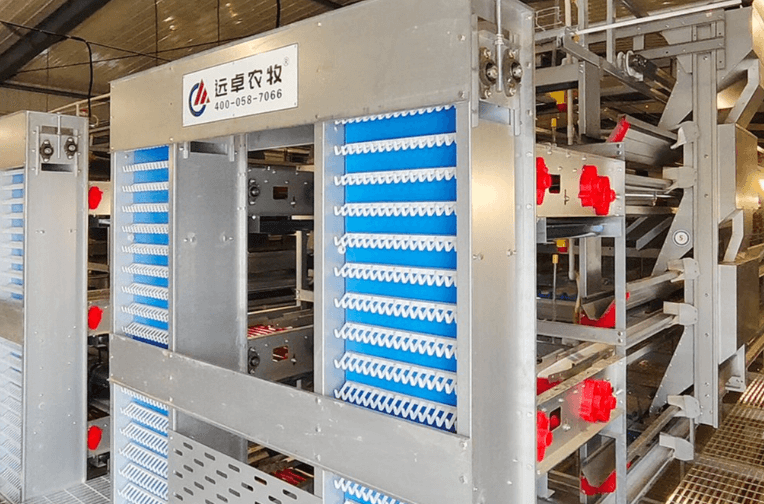

- ● Fully assembled, with high installation accuracy and smoother operation;

- ● Professional technical drinking nipple;

- ● Rationalization of manure cleaning institutions reduces the probability of fecal deviation to the lowest level, making manure cleaning more thorough;

- ● Featuring a unique large cage design, it enhances the uniformity of the chicks;

- ● Reasonable design of the front network to prevent chicken running;

- ● Independent adjustment of water line, controllable height of single line;

- ● There are two feeding methods to choose from: crane and chain feeding;

- ● Multiple environmental control designs and triple warning systems ensure property safety.

Egg chicken farming equipment, also known as egg chicken cages, is a popular form of raising chickens in high-density and large-scale modern farming. The reason for this is the adoption of a fully enclosed farming model, which separates humans from chickens, reduces the invasion of foreign chicken diseases, prevents cross infection, and lowers medication costs. The entire equipment system is intelligently managed to achieve automated temperature control, feeding, feeding, drinking water, manure cleaning, egg picking, cleaning, labeling, egg grading, packaging and other functions, providing a comfortable environment for chickens and improving their egg production rate during the breeding process.

|

|

|

Product Parameters

Comprehensive introduction of product information

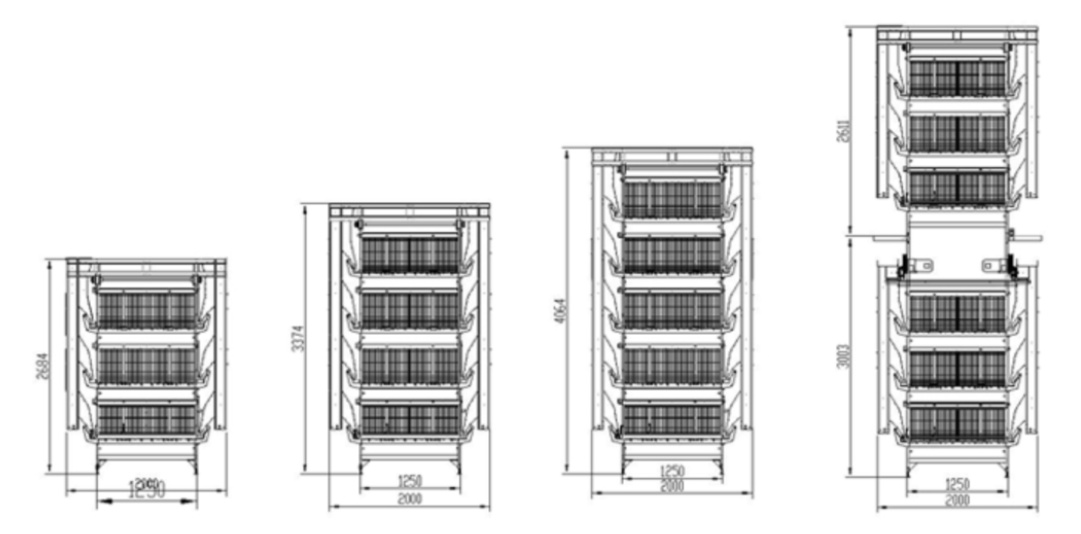

The 1.2-meter frame type stacked brooding equipment has a cage length of 1.2 meters, a single grid width of 600mm, a depth of 625mm, a total width of 1.56 meters (from the left trough to the right trough), a total width of 2 meters for the overhead feeder, a cage height of 490mm, and a layer spacing of 690mm. Each cage is divided into 2 doors, and for chicks raised for 90 days, each door can hold 12 laying hens, with an average cage area of 312 square centimeters per chicken. The number of animals raised in each group on the third floor is 144, and the number of animals raised in each group on the fourth floor is 192.

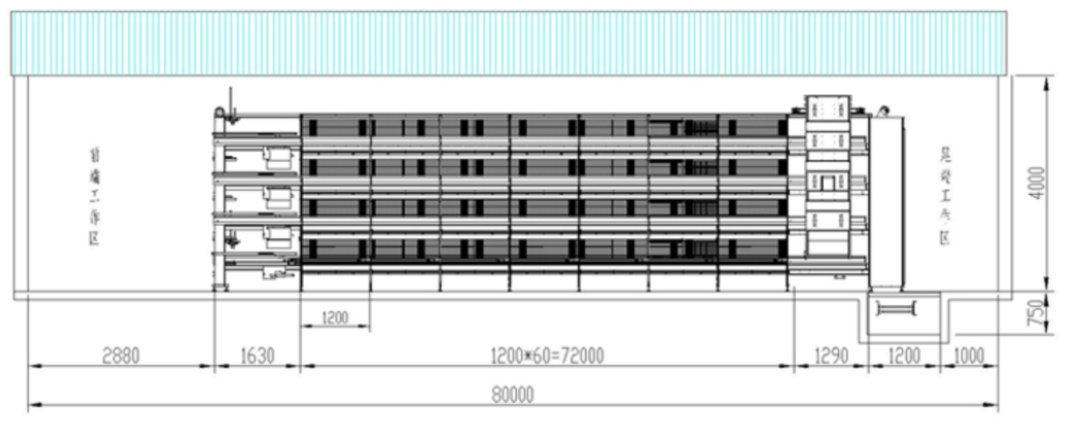

The recommended size for the chicken coop is 80 to 100 meters in length and 12.5 to 16 meters in width. The picture shows a single batch of 46080 animals raised in a 90 day period with a length of 80 meters, a width of 12.5 meters, four columns and four layers.

The 1.2-meter frame style brooding cage has a three-layer feeder height of 2.684 meters, a four layer feeder height of 3.374 meters, a five layer color roller height of 4.064 meters, and a six layer feeder height of 5.614 meters. Add a height of 24 centimeters for the feeding and mixing cage on top of the crane feeder.

Product features and advantages

Comprehensive introduction of product information

Choose OurNine Reasons

One Stop Service Provider for Intelligent Poultry Farming Equipment

Strong Brand Strength

The company has been awarded honors such as National High tech Enterprise, National Science and Technology Small and Medium sized Enterprise Quality Certification ISO9001, etc

Source Factory

The company strengthens its competitiveness through digital management (ERP/MES), technological upgrades (automation equipment), and talent cultivation, ultimately achieving comprehensive leadership in cost, quality, and speed.

Good Industry Reputation

There are many benchmark customers and great industry influence. We have established partnerships with over 1000 breeding farms and accumulated a wealth of successful cases. Provide closed-loop services for the entire industry chain, collaborate with the industry chain, and improve customer breeding efficiency;

Professional R&D team

Based at the forefront of the industry, with 16 years of experience in the research and development of poultry farming equipment and over 20 patented technologies. Continuously innovating technology and upgrading products to provide customers with more intelligent and efficient solutions for poultry farming equipment.

One-Stop Solution

Plan the overall benefits of the industry for clients, so that they can avoid detours and maximize their profits. From planning+equipment+management full cycle services, we provide customers with peace of mind, smoothness, and peace of mind!

Rich Practical Experience

Our company has a breeding experimental base for 200000 laying hens. Through hands-on breeding experiments and optimization, we deeply explore customer breeding needs, constantly innovate and improve, and make our products more perfect;

Professional Installation Team

Our own installation team can improve the delivery quality and customer experience of breeding equipment projects through standardized processes and refined management. Develop installation and construction plans, with controllable project cycles, fast response times, high efficiency, standardized operations, high installation accuracy, fewer after-sales problems, stable equipment operation, customer peace of mind, and high customer satisfaction and repurchase rates. Regular centralized training, updating technical specifications to ensure compliance with industry standards.

Good After-Sales Service

24-hour accompanying service, resource allocation, and rapid response to personnel arrangements. Continuous technical upgrades and training, regularly providing customers with technical consultation, equipment maintenance, operation training, and chicken service.

Independently Developed Management System

Integrating new generation information technologies such as artificial intelligence, Internet of Things (IoT), and big data analysis, through visual management methods, comprehensive production data statistical analysis, and feedback to customers to optimize management decisions and generate cost reduction and efficiency improvement suggestions. By combining digitalization and the Internet of Things, the production work of farms can be made more convenient and efficient, saving manpower and resources.