The seven advantages of caged egg-laying ducks have begun to emerge, and Yuanzhuo Agriculture and Animal Husbandry empower the development of the egg-laying duck industry

To promote the development of the duck industry, Yicheng Xuanze Agriculture and Animal Husbandry Co., Ltd. has collaborated with Zhengzhou Yuanzhuo Agriculture and Animal Husbandry to build two demonstration bases for cage egg-laying duck breeding. The project is located in Group 8, xin 垱 village, Liuhou Town, Yicheng City, Xiangyang, Hubei Province.

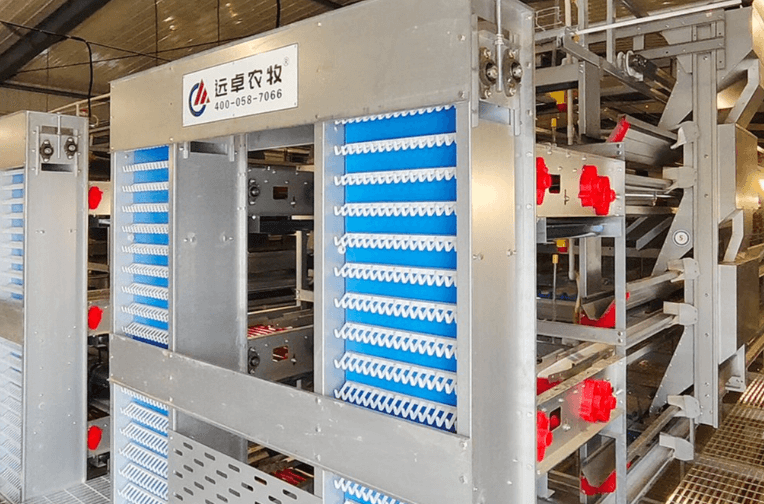

The person in charge introduced to Chengcheng that in 2021, the company invested in building a fully enclosed duck house with a construction area of 1,500 square meters. It adopted the five-row and five-story stacked design of Zhengzhou Yuanzhuo Agriculture and Animal Husbandry, and raised 40,000 laying ducks. It is equipped with a fully automated constant temperature control system, ventilation system, sprinkler system, feeding system, drinking water system, egg collection system and conveyor belt manure cleaning system, achieving automatic control of the breeding environment, precise feeding and scientific management. The temperature in the duck house is maintained at around 27 ℃ all year round, making the ducks live very comfortably. The demonstration base for cage rearing of egg-laying ducks currently has an egg production rate of 93%, with good egg quality, easy prevention and control of egg-laying duck diseases, and controllable temperature and humidity.

Compared with traditional breeding, caged laying ducks have seven major advantages:

The first is to enhance the utilization efficiency of duck houses per unit area. Cage rearing does not require sports fields or water surfaces. It adopts a multi-row and multi-layer three-dimensional frame egg-laying duck cage breeding method, which makes full use of space. The number of ducks raised per unit area is more than three times higher than that of the traditional method, greatly improving the utilization efficiency of the duck house per unit area.

The second is to enhance labor productivity. The caged egg-laying duck breeding equipment is advanced and the management procedures are standardized, which reduces the labor intensity and effectively improves the labor productivity. The number of ducks managed by each breeder can increase by more than 2 to 3 times.

Third, it is conducive to the prevention and control of diseases. The production process of caged egg-laying ducks takes place in duck houses, which isolates the ducks from direct contact with the external environment, effectively reducing the risk of infection from pathogenic microorganisms in the external environment. Due to the limited activity space, the epidemic prevention time is shortened, and the phenomenon of flock alarm and missed prevention is avoided. The health status of the ducks can be detected in time, and early detection and early treatment can be achieved, effectively reducing the risk of large-scale flock infection with diseases.

The fourth is to enhance the economic benefits of breeding. Cage rearing technology is less prone to the phenomenon of food competition. The mobile walking feeding ensures uniform feeding, making the egg-laying ducks of similar size, with even weight and uniform laying time. Coupled with the small range of movement, it reduces the amount of exercise and physical exertion, thereby lowering feed costs and significantly increasing the egg-laying rate.

Fifth, it is conducive to environmental protection. Due to the lack of strict management and social behavioral constraints, traditional breeding methods have a weak capacity for centralized waste treatment, resulting in excessive carrying capacity per unit area and exacerbating environmental pollution. During the cage rearing process, ducks are in a relatively closed environment. The pollution sources during the breeding process are confined to the breeding site. The excrement produced is convenient for centralized collection. After appropriate treatment, it can be discharged up to standard or reasonably utilized, and will not cause serious pollution or harm to the environment.

Sixth, improve the cleanliness and breakage rate of egg products. Caged laying ducks are conducive to achieving clean production and reducing the incidence of egg contamination and infectious diseases. The eggs freshly laid by cage-raised laying ducks are transported to the egg collection frame due to the slope and gravity, without direct contact with the ducks, thus avoiding damage from trampling, rolling or collision. This effectively reduces the damage rate, lowers the degree of contamination of the duck eggs, and relatively completely retains the outer membrane of the eggshell. It is conducive to extending the freshness and shelf life of the duck eggs, improving their appearance, and reducing the egg-washing process in egg product processing. Enhance the market competitiveness of duck eggs.

The seventh is to effectively control the influence of environmental temperature to ensure productivity. The caged duck house is equipped with ventilation and insulation facilities, which can regulate the indoor temperature and humidity of the duck house, unaffected by the outdoor weather conditions, ensuring normal temperature throughout the four seasons. This provides the most comfortable production environment for laying ducks, maximizes the production volume of laying ducks, and ensures that the egg-laying rate reaches over 90% throughout the year.

The successful construction of the egg-laying duck cage breeding demonstration base in Yicheng, Hubei Province, has provided a replicable and scalable new breeding model for the egg-laying duck industry of Yuanzhuo Agriculture and Animal Husbandry towards scale, industrialization and intensification. Currently, the Yuanzhuo Agriculture and Animal Husbandry Xiangyang Yicheng five-row eight-layer fully automatic cage breeding demonstration base for egg-laying ducks is under construction and is expected to be put into operation by the end of this year. It will further play an important role in promoting the healthy and stable development of the duck industry.