Chicken Manure Air Drying Equipment

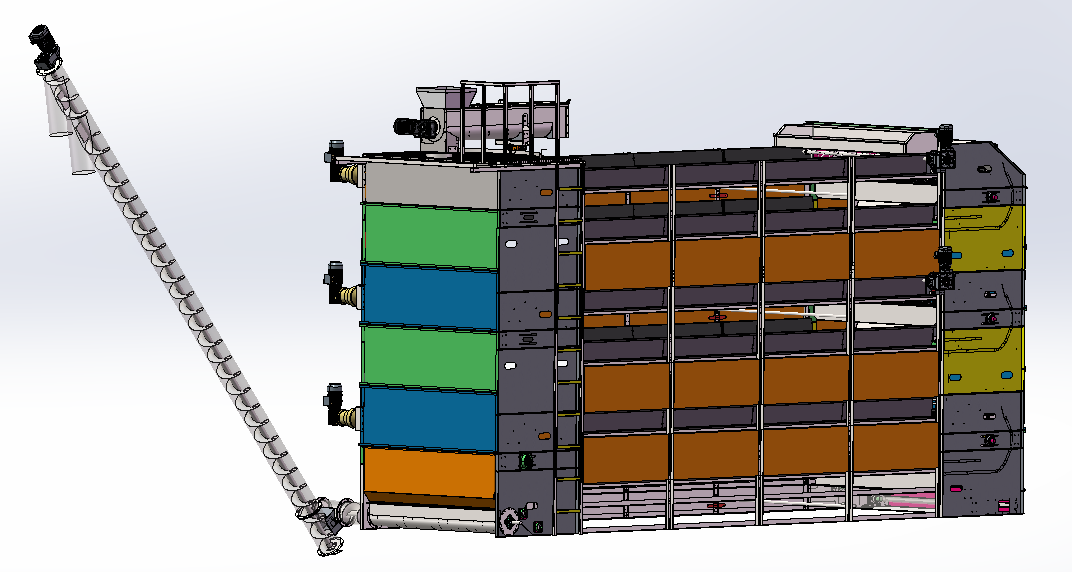

- 1. Utilize the heat released from the tail end of the chicken coop to reduce the moisture content of fresh chicken manure to below 25% within 48 hours.

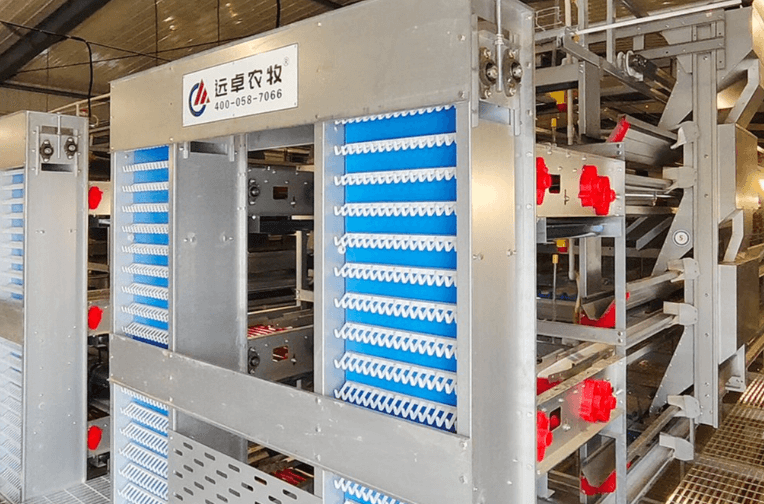

- 2. The chicken manure air drying equipment is a chain plate type air drying device that transports materials on many interconnected porous manure plates.

- 3. The dry wet mixing device can mix a small amount of dry material with wet material and evenly spread it on a porous manure board.

- 4. Wet materials are laid flat on porous steel plates and air dried. When hot air passes through the pores of the manure plate and the materials, it evaporates to remove moisture.

- 5. Wet materials are transported through porous fecal boards, and when they reach the end, they fall onto the lower fecal board for further drying.

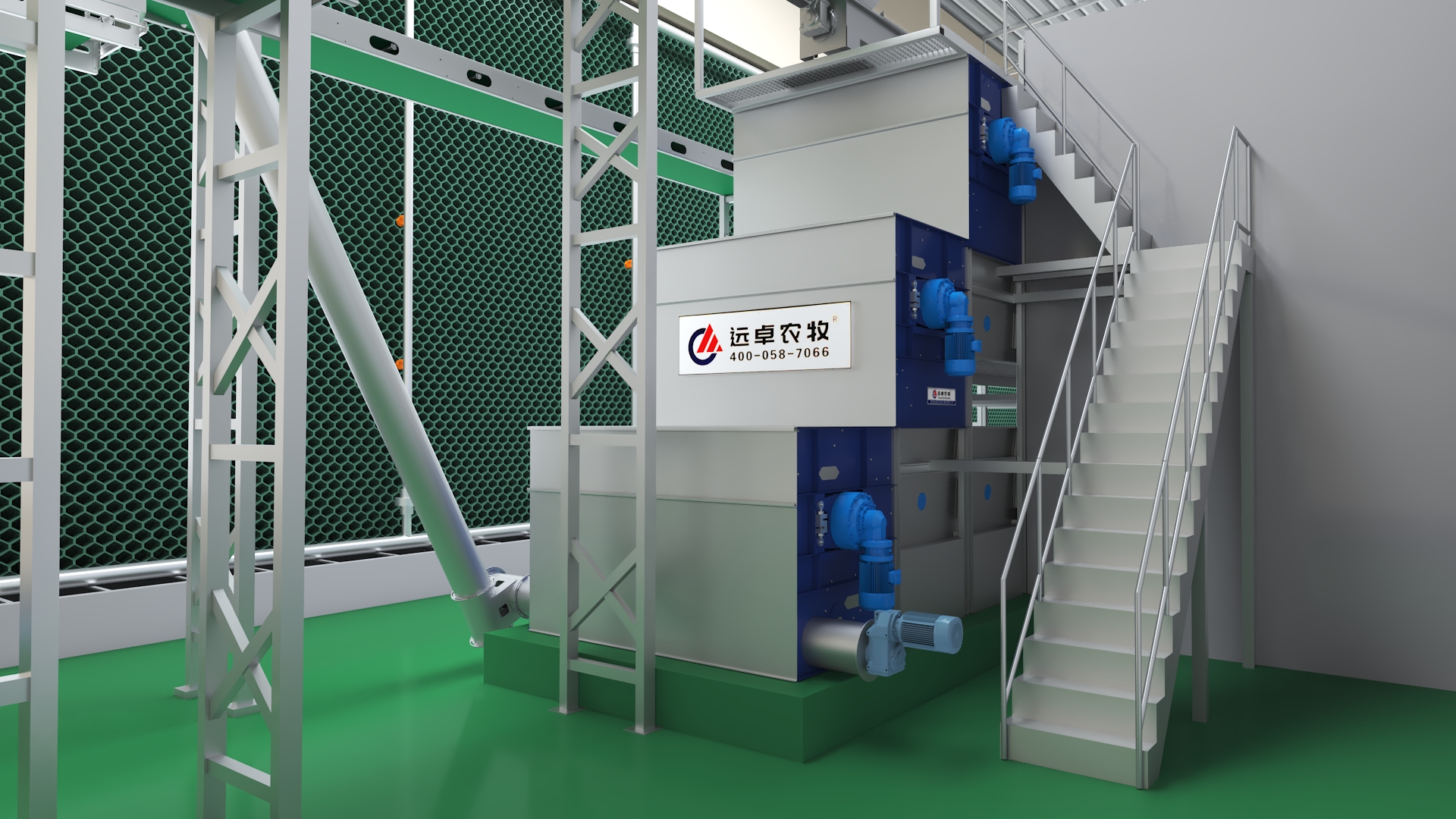

- 6. The dry materials that reach the end of the lowest conveyor plate will be transported by the discharge winch to the storage bin, and then enter the dry manure warehouse (connected to the granulation equipment).

Fresh chicken manure to be dried is transported by a conveyor belt to a dry wet mixer (which can swing left and right to mix up to 1/3), and the chicken manure is repeatedly and evenly dispersed on a manure board. There are dense circular ventilation holes on the fecal board. When the poultry manure is transported to the end of the upper manure board and falls onto the lower manure board, it continues to dry. Until reaching the bottom of the manure board (below 20%), dry manure is output by the discharge auger and sent to the dry manure warehouse.

|

|

|

Product Parameters

Comprehensive introduction of product information

Under various environmental conditions, the poultry manure air drying equipment can air dry fresh chicken manure into multi-element organic fertilizer that is easy to store and transport within 24 hours without polluting the environment, creating high additional profit points for customers!

Product features and advantages

Comprehensive introduction of product information

Choose OurNine Reasons

One Stop Service Provider for Intelligent Poultry Farming Equipment

Strong Brand Strength

The company has been awarded honors such as National High tech Enterprise, National Science and Technology Small and Medium sized Enterprise Quality Certification ISO9001, etc

Source Factory

The company strengthens its competitiveness through digital management (ERP/MES), technological upgrades (automation equipment), and talent cultivation, ultimately achieving comprehensive leadership in cost, quality, and speed.

Good Industry Reputation

There are many benchmark customers and great industry influence. We have established partnerships with over 1000 breeding farms and accumulated a wealth of successful cases. Provide closed-loop services for the entire industry chain, collaborate with the industry chain, and improve customer breeding efficiency;

Professional R&D team

Based at the forefront of the industry, with 16 years of experience in the research and development of poultry farming equipment and over 20 patented technologies. Continuously innovating technology and upgrading products to provide customers with more intelligent and efficient solutions for poultry farming equipment.

One-Stop Solution

Plan the overall benefits of the industry for clients, so that they can avoid detours and maximize their profits. From planning+equipment+management full cycle services, we provide customers with peace of mind, smoothness, and peace of mind!

Rich Practical Experience

Our company has a breeding experimental base for 200000 laying hens. Through hands-on breeding experiments and optimization, we deeply explore customer breeding needs, constantly innovate and improve, and make our products more perfect;

Professional Installation Team

Our own installation team can improve the delivery quality and customer experience of breeding equipment projects through standardized processes and refined management. Develop installation and construction plans, with controllable project cycles, fast response times, high efficiency, standardized operations, high installation accuracy, fewer after-sales problems, stable equipment operation, customer peace of mind, and high customer satisfaction and repurchase rates. Regular centralized training, updating technical specifications to ensure compliance with industry standards.

Good After-Sales Service

24-hour accompanying service, resource allocation, and rapid response to personnel arrangements. Continuous technical upgrades and training, regularly providing customers with technical consultation, equipment maintenance, operation training, and chicken service.

Independently Developed Management System

Integrating new generation information technologies such as artificial intelligence, Internet of Things (IoT), and big data analysis, through visual management methods, comprehensive production data statistical analysis, and feedback to customers to optimize management decisions and generate cost reduction and efficiency improvement suggestions. By combining digitalization and the Internet of Things, the production work of farms can be made more convenient and efficient, saving manpower and resources.