Don't let negative pressure become a burden on raising chickens

1、 Definition of Negative Pressure

Negative pressure refers to the state in which the gas pressure inside the chicken coop is lower than the external atmospheric pressure. In a closed chicken coop, negative pressure is formed by actively drawing air through a fan and passively introducing air. Turning on the fan will create a pressure difference inside and outside the chicken coop, which is called negative pressure. The negative pressure value can be obtained by measuring the pressure difference inside and outside the chicken coop, usually using pascals (Pa) or inches of water column (inch wc) as units.

Static negative pressure: When there is no air flow, the characteristic of negative pressure is static negative pressure, where the pressure at each point inside is consistent, that is, the negative pressure at the front, middle, and back is the same. Static negative pressure is an important indicator for measuring the sealing performance of a chicken coop.

Dynamic negative pressure: In chicken coops with small windows, negative pressure value is an indirect method of measuring wind speed through small windows. The greater the pressure difference between indoors and outdoors, the greater the wind speed entering the chicken coop; The smaller the pressure difference, the lower the wind speed.

2、 The function of negative pressure

Chickens do not require negative pressure, nor do humans. It is a comprehensive requirement of season, building mode, heating mode, and ventilation mode. The main function of negative pressure is to optimize the chicken coop environment by controlling air flow. Appropriate negative pressure can provide fresh air, maintain appropriate air quality, and eliminate harmful gases, dust, and moisture.

The negative pressure size also has a significant impact on the chicken flock:

1. Excessive negative pressure

If chickens can adapt, there is usually no problem. But if the chicken flock has respiratory diseases, excessive negative pressure may cause them to feel suffocated and lack oxygen, exacerbating the condition. When using a fan water curtain in summer, the respiratory rate of the chicken flock is high, and excessive negative pressure will increase the burden of lung ventilation. For chicks, a slightly lower negative pressure is beneficial for the development of internal organs.

2. Insufficient negative pressure

When the external temperature is below 5 degrees Celsius inside the house, if the negative pressure is too low, the cold air cannot be fully mixed with the warm air on the roof, which may cause the chickens to catch a cold and harmful gases cannot be quickly discharged. When opening the wet curtain for cooling in summer, the low negative pressure cannot generate high wind speed, which may cause the cool air to not reach the back of the chicken coop, resulting in a large temperature difference between the front and back, increasing the stress response of the chicken flock and easily causing diseases.

3、 How to determine the appropriate negative pressure for a chicken coop - negative pressure balance point

Reasonable negative pressure control is not only beneficial for the healthy breeding of chicken flocks, but also saves the cost of raising chickens, promotes the healthy growth of chicken flocks, and creates a good ventilation environment in the chicken coop. Therefore, we need to find the most reasonable negative pressure, that is, the negative pressure balance point. However, due to the differences in the structure and equipment of chicken coops, there are differences in the negative pressure balance points of different chicken coop structures.

The following is a control method for the negative pressure balance point in the chicken coop that can be used as a reference:

1. Principle of Negative Pressure Balance Point

In winter, cold air slowly enters the chicken coop through small windows along the roof, and then slowly descends to fully mix with the hot air inside the coop, avoiding the chickens from getting cold and reducing humidity.

2. Principle of Negative Pressure Balance Point Control

(1) The width of the chicken coop affects the negative pressure balance point. The wider the coop, the higher the negative pressure balance point is required to ensure that air can reach the center of the coop.

(2) The temperature difference between the inside and outside affects the negative pressure balance point, and the larger the temperature difference, the larger the negative pressure balance point required. In winter, the air density is high, and a larger negative pressure is required to draw air into the chicken coop, corresponding to a higher negative pressure equilibrium point; In summer, with high temperatures and low air density, a smaller negative pressure can ensure the circulation of air in the chicken coop, corresponding to a lower negative pressure equilibrium point. Therefore, when setting the negative pressure balance point, low pressure is set for high temperature outside, and high pressure is set for low temperature outside.

(3) Different seasons and external temperatures require the determination of different negative pressure values and the measurement of different negative pressure equilibrium points.

3. Monitoring method for negative pressure balance point

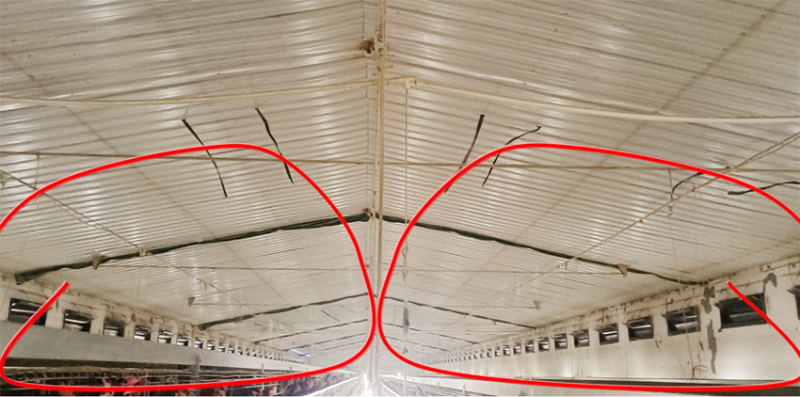

(1) Install the ribbon and observe the consistency of the front and rear ribbons

Choose the roof of the chicken coop at the front, middle, and back positions, and hang the ribbons symmetrically.

Determine the number of fans to be turned on based on the minimum respiration rate of chickens at different temperatures and ages, while ensuring that the intake air volume is twice the exhaust air volume, and determine the size of the small window opening.

At this point, check the consistency of the front, middle, and rear ribbons to ensure that the wind reaches the middle of the chicken coop evenly, and record the negative pressure value.

(2) Conduct a smoke test and record the time it takes for smoke to reach the middle of the chicken coop

When the house is empty, release the smoke bomb, turn on a fan, adjust the opening angle of the small window, and observe the mixing effect of the smoke bomb. After ensuring that the smoke reaches the predetermined effect, record the time from the small window to the chicken house through the smoke experiment video, ensuring that the time difference between the front, middle, and back does not exceed two seconds, in order to determine the negative pressure balance point, optimize the ventilation effect, reduce the problem of wind deviation, and improve the health of the chicken flock.

(From left) Low negative pressure - High negative pressure - Suitable negative pressure

(3) Consistency of wind speed across different small windows

Daily monitoring of the consistency of the size and wind speed before and after the small window is necessary to prevent local negative pressure from being too high or too low, which may affect the uniformity of ventilation.

Monitor the wind speed at the turning point. When one fan is turned on, the wind blows to the middle of the chicken coop, and the optimal wind speed for the turning point to fall is 0.42 meters per second.

(4) Monitor the minimum temperature difference at different points

Hang thermometers in the front, middle, and back of each aisle, record the temperature difference at different points in the chicken coop under different negative pressures, and find the negative pressure value with the lowest temperature difference.

For example, if the temperature in the middle aisle is low, the negative pressure may be too high, causing the cold air to enter too quickly and fall too much. If the temperature on both sides is too low and the middle aisle is too high, consider that the negative pressure is too low, and the cold air cannot reach the middle position, causing it to fall early and resulting in low temperature on both sides.

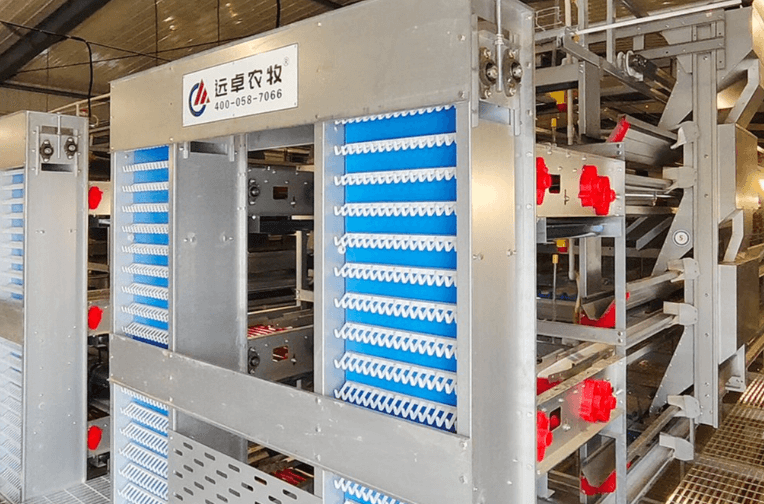

After adjusting the negative pressure, the temperature at each position is uniform, with a temperature difference of within 1 degree for A-type equipment and within 2 degrees for H-type equipment, indicating that the negative pressure is relatively reasonable.