Are there any particular rules for putting laying hens in cages? What should be noted when putting laying hens in cages?

Nowadays, when raising laying hens, we usually adopt cage rearing methods. This can provide laying hens with a relatively healthy and safe production environment, thereby enhancing their egg-laying capacity. Cage rearing can also reduce the spread and infection of diseases and play a role in facilitating management. When transferring the laying hens into the cage, it is essential to operate correctly. If the operation is incorrect, it will affect the production of the laying hens. So, what issues should we pay attention to when putting laying hens into cages? Let's take a look together below.

1. Cage age

The suitable age for laying hens to be caged is generally between 13 and 18 weeks of age. This can well ensure that the weight of young laying hens remains within the normal standard, and at the same time, it can also increase their egg production rate during the breeding process. What we need to pay attention to is that the later time for cage loading should not be later than twenty weeks of age. When the flock of chickens is growing well, we can also continue to screw them into cages at the age of 60 days. When loading the cages, we also need to group and batch the laying hens according to their different growth conditions.

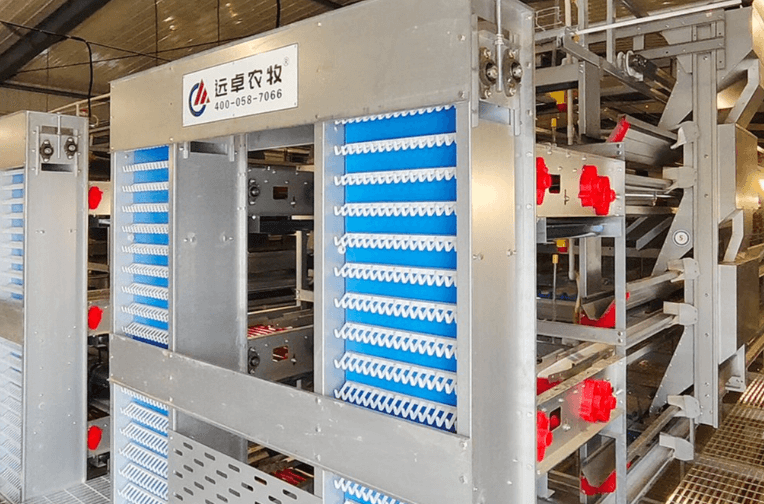

2. Facilities and equipment

After laying hens are placed in cages, we still need to ensure their original growth environment; otherwise, this will also affect their growth and production. Before loading the cages, we need to be equipped with the corresponding breeding equipment and install various breeding facilities. Also, strict maintenance and replacement of these facilities and equipment should be carried out to avoid problems in the later breeding process.

3. Scientific chicken catching

When putting laying hens into cages, we must be scientific. The noise should not be too loud. We must handle them gently and not apply excessive force. We must not disturb the flock of hens, otherwise it will cause an excessive reaction, which will have a very significant impact on the growth and production of laying hens. Generally, for chicken flocks that are subject to stress responses, their appetite will decrease and then gradually weaken, seriously affecting the health of the flock.

4. Prevent the incidence rate from rising

When loading laying hens into cages, the operation must be correct. Moreover, after loading, it is essential to pay attention to the changes in temperature differences and adjust the temperature reasonably. Generally, the cages are loaded at night, and after loading, the feeding is improved. A balanced and nutritionally balanced feed is reasonably configured, and scientific chemical control is carried out. This can prevent the occurrence of some diseases and improve the quality of laying hens.

5. Prevention and control of parasites

To ensure the health of laying hens and their subsequent production, we need to deworm them. Especially when the laying hens are 60 days old and 120 days old, this is when we are putting them in the cages. When loading the cages, we should feed the deworming medicine according to the scientific instructions for medication to prevent and control parasites.

6. Keep the chicken flock relatively stable

Maintaining the relative stability of the chicken flock is actually quite simple. It's just about putting chickens in the same pen and barn as much as possible. Under normal circumstances, when unfamiliar chickens enter a new environment, phenomena such as competing for food, water and position will occur, which has a very significant impact on the production of laying hens. Therefore, it is essential to avoid such situations.

The above points are what the editor wants to share with you today about the issues to be noted when putting laying hens in cages. We hope everyone will pay attention to them. Although these are all minor incidents, they have a significant impact on the growth and development of laying hens as well as their egg production rate.

Zhengzhou Yuanzhuo Agricultural and Animal Husbandry Equipment Co., Ltd. is located in the western suburbs of Zhengzhou, the provincial capital. It is an integrated enterprise specializing in the research and development, production, sales, installation and after-sales service of agricultural and animal husbandry equipment. The company's main products include Stacked (brooding, laying hens, broilers, laying ducks, meat ducks) automated breeding equipment, stepped (brooding, laying hens, broilers, laying ducks, meat ducks) automated breeding equipment, mixed breeding chicken automated breeding equipment, fully automatic egg collection equipment, belt-type manure cleaning machine, fully automatic feeding machine, ordinary manure cleaning machine series, intelligent environmental controller for breeding farms As well as breeding equipment such as fans, water curtains, manure extractors and hot air furnaces.

The equipment produced by our company features a reasonable structure, stable performance and durability. The equipment adopts hot-dip galvanizing surface treatment process, and its normal service life is more than fifteen years.