Promote the high-quality development of the egg-laying chicken industry through digitalization and intelligence

The egg-laying chicken industry was the first in the livestock industry to achieve large-scale production. After more than 40 years of development, it has entered an era of low profits with saturated stock. In the new historical stage, how can the egg-laying chicken industry practice high-quality development and become a livelihood industry that avoids internal competition, has reasonable profits and improved efficiency?

At the "11th China Egg-Laying Chicken Industry Development Conference" held from November 15th to 17th, 2023, a special report titled "Practice and Application of Digitalization and Intelligence in the Egg-laying Chicken Industry" was shared in light of the national digital economy policies and the current digital status of the egg-laying chicken industry. It is pointed out that in the era of digital economy, only through digital and intelligent transformation can the egg-laying chicken industry enhance efficiency and benefits and achieve high-quality development!

The integration of "software, hardware and intelligence" accelerates the breeding of domestic laying chicken breeds

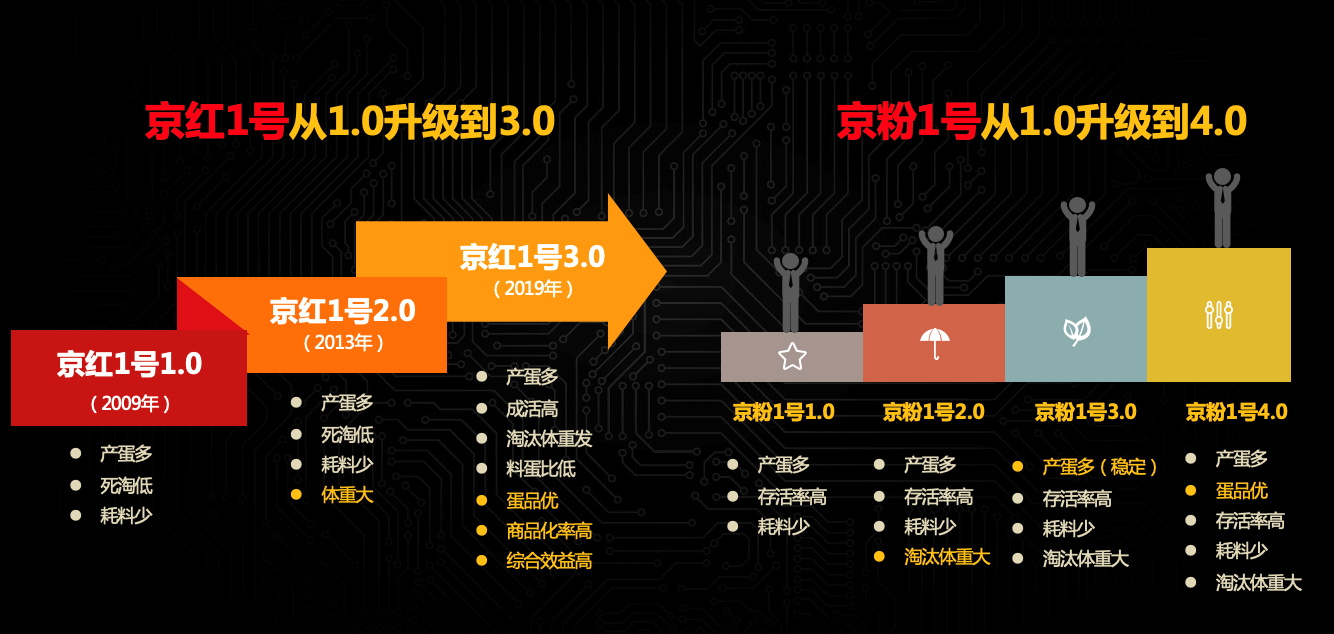

"Planting" is the source of the development of the egg-laying chicken industry and also the foundation for ensuring the high-quality development of the industry. Looking back on the development over the past four decades, China's egg-laying chicken breeding industry has gone through three stages: "independent breeding, introduction from abroad, and coexistence of self-breeding and introduction". Meanwhile, the corresponding breeding techniques have been continuously upgraded and iterated with the advancement of science and technology, evolving from traditional breeding and molecular breeding to big data breeding and intelligent breeding.

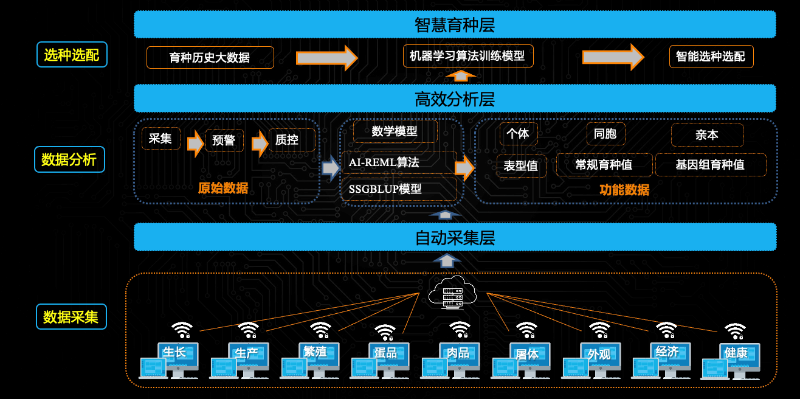

Through the integration of "software, hardware and intelligence", a smart breeding management platform has been developed and constructed. Based on diverse materials, it automatically collects breeding data for all traits, the entire cycle and all generations through intelligent equipment. At the same time, a distributed storage system is used to ensure efficient computing. Ultimately, it realizes intelligent decision-making in breeding and increases the breeding efficiency of domestic laying hens by more than 50%.

The intelligent breeding management platform, centering on breeding goals and relying on artificial intelligence for selection and mating, on the one hand, continuously improves the performance of domestic laying chicken breeds and achieves breed upgrading; On the other hand, by leveraging big data to identify special traits, the development of new varieties has been accelerated. The new variety of Jingfen No. 6, which is unique to China and the world, has achieved internationally leading production performance.

The Internet of Things, data and intelligence are integrated to create a new model of modern breeding

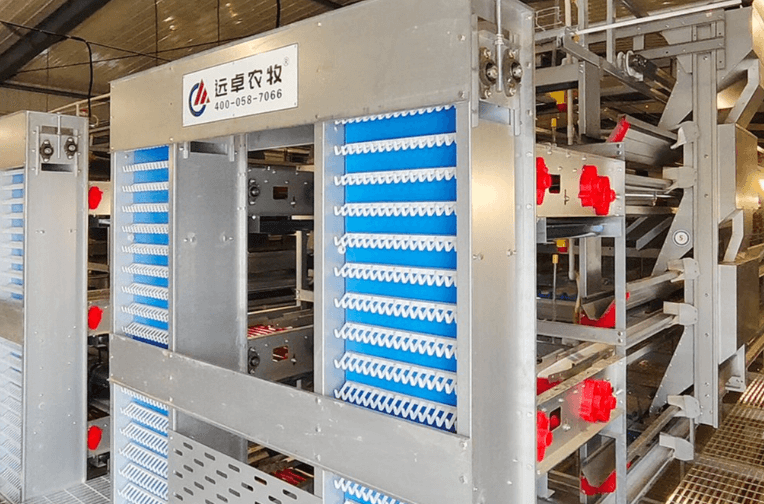

"Raising" is the key to the development of the laying hen industry. China's large-scale egg-laying (breeding) chicken farming started with automation. With the acceleration of the informatization process, it has now entered the digital farming stage. At the same time, relying on the Internet of Things, it is developing towards intelligence and wisdom. Create a new modern breeding model that integrates Internet of things, data and intelligence to enhance the efficiency and benefits of breeding.

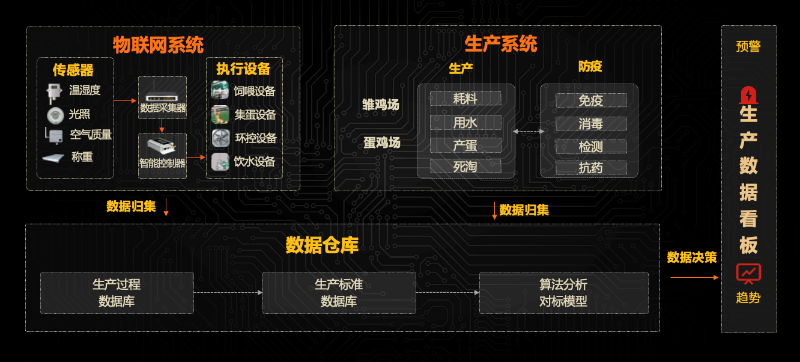

Internet of Things: Based on the Internet of Things (iot) intelligent equipment, the equipment end is connected to automatically collect basic data such as the environment, feed consumption, drinking water, and energy input during the egg-laying chicken breeding process.

Number couplet: Supported by the production management system, the breeding end is connected to achieve the collection and connection of growth data, production data and cost data throughout the entire breeding process.

Zhilian: Integrate equipment data with breeding data, connect the data terminals, and establish an intelligent decision-making and analysis system centered on batch management to assist managers at all levels in intelligent decision-making and early warning management.

As a sunrise industry for people's livelihood, China's egg-laying chicken industry has developed over the past four decades and has become the world's largest egg-laying chicken industry country in terms of breeding scale, egg production and egg consumption. Entering the new era of digital economy, the innovative integration of biotechnology and information technology has become the "intelligent" high point of industrial development. Building an industrial Internet platform through digitalization and intelligence to enhance industrial efficiency and benefits will surely effectively promote the high-quality development of the egg-laying chicken industry!