Innovative egg-laying duck farming model: Ducks Move into "air-conditioned rooms" in Yicheng, Hubei

On July 6th, when entering the breeding base of Yicheng Xuanze Agriculture and Animal Husbandry Co., Ltd. located in Group 8, Xinjun Village, Liuhou Town, Yicheng City, Hubei Province, a cool breeze greeted you, forming a sharp contrast with the scorching summer heat. One could see the ducks in layer upon layer of cages, either grazing, drinking water or taking a short rest, looking very relaxed and content. It turns out that all the ducks here have moved into "air-conditioned rooms" and are living a comfortable life.

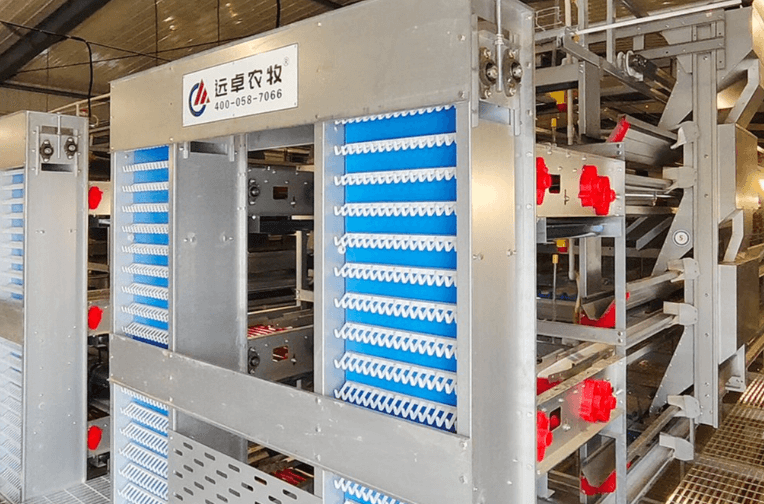

Ducks have moved into "air-conditioned rooms" (Photo by Wang Ying)

What are there in the "air-conditioned room"? The company's person in charge introduced to Chengcheng that this is a fully enclosed duck house invested and constructed in 2021, with a construction area of 1,500 square meters. It adopts a five-row and five-story stacked design, raising 40,000 laying ducks in a single building. It is equipped with a fully automated constant temperature control system, ventilation system, sprinkler system, feeding system, drinking water system, egg collection system, and conveyor belt manure cleaning system. It has fully achieved automatic control of the breeding environment, precise feeding and scientific management. "The temperature in the duck house is maintained at around 27 or 28 degrees Celsius all year round, with a spring-like climate all year round. The ducks live very comfortably."

What are the advantages of this multi-layer three-dimensional cage rearing mode? Xiang Chengcheng introduced that compared with the traditional ground-level flat breeding model, this multi-level three-dimensional breeding method saves labor. Previously, one person could only raise at most three to five thousand egg-laying ducks, but now one person can manage 40,000 egg-laying ducks. Traditionally, raising 10,000 ducks requires 8 to 10 mu of land, but now raising 40,000 laying ducks only needs two or three mu of land.

In addition, this mode can achieve automatic control of temperature and humidity, maintaining a constant temperature throughout the four seasons, providing a comfortable living environment for ducks, reducing environmental stress, and facilitating the stable performance of laying ducks in production. The egg-laying rate during the production period remains at around 93%.

The fully enclosed management ensures that the ducks are healthy and free from diseases. The manure and sewage are collected and treated centrally through the conveyor belt and all are returned to the fields nearby for utilization, achieving zero discharge of manure and sewage. "Ducks in such houses eat well, live well, stay healthy, have a high egg-laying rate, and it's also easier for us to manage them." "

It is learned that the Agricultural and Rural Affairs Bureau of Yicheng City has promoted the intensive, fully enclosed three-dimensional multi-layer cage breeding technology of egg (meat) ducks as the main model for standardized ecological and efficient livestock and poultry breeding throughout the city. So far, 15 cages have been built, with a breeding scale of 740,000 ducks. It is planned to build and promote 40 cages within two years, with a breeding capacity of up to 2 million ducks.

- Previous: A new model of cage rearing for egg-laying ducks has been innovated, with a constant temperature of 27℃. In Yicheng, Hubei Province, General Manager Xiang is "pushing the ducks onto the shelves"

- Next: The vigorous "livestock" momentum ignites the flame of entrepreneurship # Veterans Shine in Central Plains, leading the way in agriculture and animal husbandry. Chinese veterans