Analysis of the ways to convert poultry manure resources into green energy

China is the world's largest poultry farming country. According to statistics, in 2021, China's poultry egg production reached 33.52 million tons and poultry meat production reached 24.78 million tons, indicating a huge amount of poultry farming. Accompanying this is the generation of massive amounts of poultry manure. Roughly estimated, the total amount of poultry manure in China exceeds 1 billion tons annually. If a large amount of poultry manure is not treated properly, it will inevitably cause serious pollution to soil, water bodies, atmosphere, etc. The report of the 20th National Congress of the Communist Party of China proposed to develop green and low-carbon industries and promote the green transformation of agriculture. Converting poultry manure into clean energy is of great significance for accelerating the construction of a green, low-carbon, and circular agricultural industry system, and helping to achieve carbon peak and carbon neutrality goals.

1、 The necessity of converting poultry manure resources into green energy

1. The need to alleviate environmental pollution pressure

For a long time, there has been a lack of effective management and scientific utilization in the treatment of livestock and poultry manure in China. A large amount of livestock manure is indiscriminately discarded and stored in the open air, and the organic matter, nitrogen and phosphorus contained in it are lost in the wind and sun, polluting the environment. According to estimates, the annual loss of nitrogen and phosphorus caused by improper treatment of livestock and poultry manure in China reaches 5 million tons and 2.9 million tons respectively, posing a significant threat to surface water, groundwater and other water bodies. Harmless treatment and resource utilization of livestock manure can reduce pollutant emissions from the source, which is of great significance for improving the living environment, protecting ecological security, and promoting ecological civilization construction.

2. The need to develop a circular economy

The 20th National Congress of the Communist Party of China proposed to promote comprehensive conservation and circular utilization of resources, implement national water-saving actions, and reduce energy consumption. Developing a circular economy is an inevitable choice for implementing the concept of sustainable development and building a resource-saving and environmentally friendly society. According to calculations, the annual conversion of poultry manure resources in China can provide 21.7776 million tons of standard coal energy. Taking biogas fermentation as an example, 5 tons of chicken manure can be processed to produce 350-400 cubic meters of biogas, equivalent to 195-22.5 kilograms of standard coal, which can meet the fuel needs of 3-4 households for one year. The biogas residue and slurry produced by manure fermentation are high-quality organic fertilizer raw materials, which can reduce the use of chemical fertilizers by more than 30% when applied to farmland, and are conducive to protecting soil fertility and developing ecological agriculture.

2、 The main way to convert poultry manure resources into green energy

1. Biogas fermentation

Biogas fermentation is a biological process that utilizes anaerobic microorganisms to ferment organic matter, converting organic components in poultry manure into combustible gases such as methane. Biogas technology is relatively mature and stable, with low equipment investment and almost no discharge of wastewater or waste residue. It is currently the most widely used manure treatment technology. Biogas fermentation requires the use of facultative anaerobic bacteria to decompose organic matter such as protein and fat in feces in a closed fermentation tank under medium temperature conditions of 35 ℃~40 ℃. After three stages of hydrolysis, acidification, and methane production, the organic matter is finally converted into combustible gases such as methane and carbon dioxide. After biogas fermentation, the organic content in feces is greatly reduced, making it an excellent organic fertilizer.

Zhenghe County, Fujian Province, is a famous "hometown of Chinese tofu" in China, producing a large amount of tofu meal, soybean skin and other soy product processing waste every year. In 2020, Zhenghe County completed and put into operation the world's largest single unit biogas project for the joint treatment of soybean waste and livestock manure, with a daily processing capacity of 150 tons of manure, an annual output of 3 million cubic meters of biogas, a daily power generation of 28800 kWh, and an annual output of 10000 tons of organic fertilizer. The project adopts CSTR fully mixed fermentation process, with a fermentation tank capacity of 12000 cubic meters, equipped with automatic feeding, intelligent mixing, waste heat recovery and other devices. After biogas production, it is dehydrated, desulfurized and purified, and combined heat and power is achieved through a 500KW biogas generator set. The project effectively improved the production and quality of biogas, achieved collaborative disposal of manure, straw, and by-products of agricultural product processing, and created an ecological planting and breeding circular agriculture full industry chain, providing a successful example for the resource utilization of manure and the large-scale application of biogas engineering.

2. Composting

Suitable moisture content (50%~60%) C/N(25/1-30/1)、 The particle size (1-5cm) is a prerequisite for ensuring the smooth progress of aerobic composting, which requires frequent flipping to keep the pile loose and facilitate air circulation. During the composting process, microbial metabolism generates a large amount of heat, with a maximum heap temperature of over 70 ℃, which can kill pathogenic bacteria and weed seeds in feces. After 2-3 months of composting, the compost fermentation is basically completed, the volume of the heap is reduced by 30% to 50%, the organic matter content decreases, and nutrients such as nitrogen, phosphorus, and potassium are concentrated to form a loose and fertile organic fertilizer. Compared with biogas composting, the advantages of this method are simple process, less equipment investment, and easy on-site consumption and utilization of the organic fertilizer product.

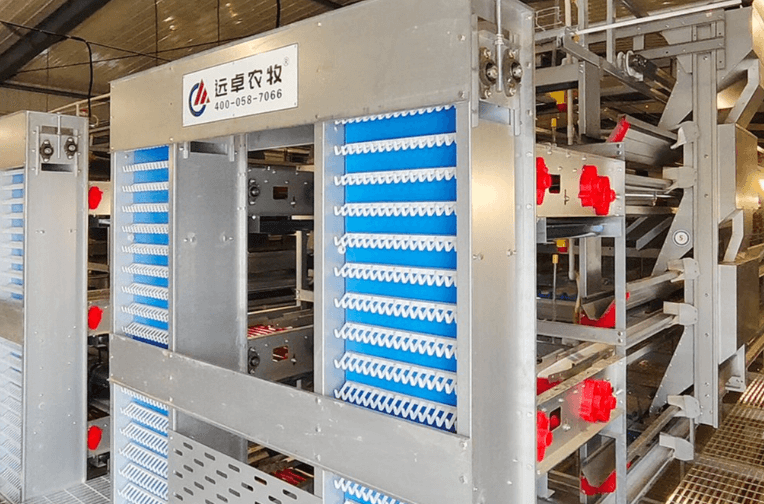

Jiaxiang County, Jining City, Shandong Province is the largest egg chicken breeding base in China, with an annual inventory of over 30 million laying hens. In 2016, the county built and put into operation a 13.33 hectare egg chicken manure composting center, equipped with turners, forklifts, and automated intelligent measurement and control systems. It processes more than 300 tons of chicken manure daily and produces over 100000 tons of organic fertilizer annually. The composting fermentation microbial agent was developed by Shandong Agricultural University Biotechnology Company. After addition, it can quickly raise the composting temperature to above 75 ℃ and shorten the composting cycle. After about 40 days of fermentation, the moisture content of chicken manure decreased from 70% to below 30%, and the nutrient content such as nitrogen, phosphorus, and potassium increased by 2-3 times. The odor of manure was basically eliminated, and the weed seed killing rate reached over 98%. The product is widely used in fruit tree and vegetable planting and is highly welcomed by farmers. The implementation of this project effectively solved the problem of chicken manure pollution, maximized the agricultural value of manure, alleviated the problems of soil compaction and soil fertility decline in farmland, and was rated as a demonstration county for promoting the resource utilization of livestock and poultry manure by the Ministry of Agriculture and Rural Affairs.

3. Pyrolysis gasification

Pyrolysis gasification is a thermochemical process that utilizes high-temperature thermal decomposition and gasification reactions to break down organic matter in poultry manure under anaerobic or low oxygen conditions, producing combustible gas and tar. During the pyrolysis and gasification process, organic macromolecules are thermally decomposed into tar, ash, and combustible gas at temperatures ranging from 300 ℃ to 500 ℃. At temperatures above 800 ℃, some of the tar and organic matter are further gasified to produce combustible gases such as CO and H2. Pyrolysis gasification has the characteristics of no pollution, no waste discharge, and high fuel calorific value, but it requires high control of process parameters and equipment materials. The energy consumption of pyrolysis gasification process is high, and it is necessary to do a good job in heat recovery and cascade utilization. The main components of pyrolysis gas include CO, H2, CH4, CO2, etc. Among them, CH4 content is about 40%, and the calorific value can reach 5000~6000 kcal/Nm ³. It can be used for industrial boilers, internal combustion engine power generation, etc. The tar and ash generated by pyrolysis can also be used as organic fertilizer raw materials to achieve waste resource utilization. The pyrolysis gasification technology has broad prospects, but currently the cost is high and it is still in the experimental demonstration stage.

Shandong Rongchang Bioengineering Co., Ltd. is the largest chicken manure pyrolysis and gasification treatment enterprise in China. The company's independently developed chicken manure pyrolysis system adopts the process route of "pyrolysis+gasification+combustion", equipped with pyrolysis furnace, cyclone dust collector, water bath tar removal, biogas tank and other devices. Chicken manure is pyrolyzed at a high temperature of 850 ℃, and the tar is collected by condensation and used as fertilizer raw material. The pyrolysis gas enters the gasifier and is further converted into synthesis gas at a high temperature of 1100 ℃. The project processes 100000 tons of chicken manure annually, produces 120000 cubic meters of synthetic gas per day, and has a calorific value of 35.59 MJ/m ³. It can replace natural gas for boiler combustion, industrial furnace heating, etc., and can reduce carbon dioxide emissions by 120000 tons per year. This project has taken the lead in breaking through the bottleneck of domestication of pyrolysis gasification equipment, with a single set of processing scale reaching the leading level in China. The production cost is reduced by 30% compared to traditional technology, and it has significant environmental and economic benefits, providing a new technological path for the resource utilization and high value-added utilization of chicken manure.

3、 Conclusion

Poultry manure is a biomass resource rich in organic matter, and its rational development and utilization can be converted into clean energy and high-quality organic fertilizer. Biogas fermentation, composting, and pyrolysis gasification are currently the main technological routes for the resource utilization of poultry manure, but they all have certain limitations. Biogas and composting processes are relatively mature, but the treatment cycle is long and the facility scale is limited, making it difficult to meet the needs of large-scale breeding farms. The pyrolysis gasification process is advanced and has high product added value, but it has high energy consumption and cost, and its engineering application is not yet mature. In the future, we should base ourselves on the actual situation of the breeding farm, choose suitable technological routes according to local conditions, optimize process integration models, vigorously promote mature and applicable technologies, and accelerate the industrialization process of advanced technologies. We need to increase policy support, improve incentive mechanisms such as subsidies for manure resource utilization, strengthen technical guidance services, enhance technological innovation and integration, and focus on breaking through bottlenecks such as low participation enthusiasm of breeding farm entities, inadequate collection of manure in the farm, and low utilization rate of resources. The collaborative efforts of the government, enterprises, and farmers can accelerate the pace of resource utilization of poultry manure, achieve a win-win situation of environmental, economic, and social benefits, and make "green mountains and clear waters" a "golden and silver mountain" for the high-quality development of animal husbandry, making positive contributions to rural revitalization and the construction of a beautiful China.